The main ingredients

Amino modified silicone emulsion.

Physical and chemical properties

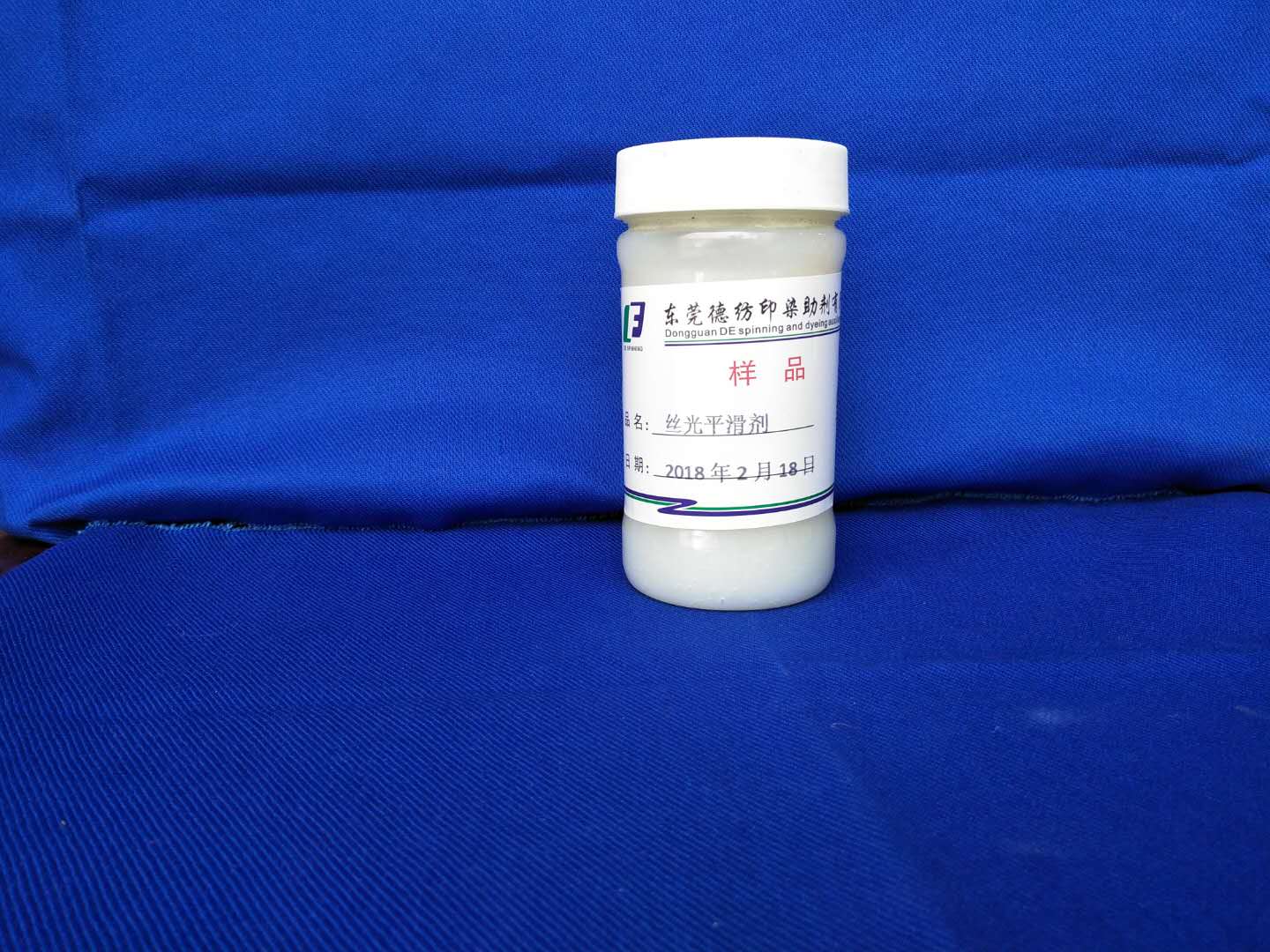

External view: milky white liquid.

Ionic: weak positive/non-ionic.

PH: 5 ~ 7

Solubility: soluble in water.

Stability (3000r/min) is not stratified, no oil.

Features and USES

Mercerizing smoothing agent is emulsion polymerization and high molecular weight group of silicone microemulsion, and fiber surface and internal crosslinking can be formed mesh permanent film, a significant reduction in the friction coefficient between the fibre, therefore make the smooth degree of the fabrics increased significantly, super soft effect concurrently at the same time. Suitable for polyester, polyurethane, acrylic, cotton and Gun spinning smooth soft finishing of knitted and woven especially is suitable for the finishing of wool and its blended fabric, yarn can also be used to smooth finishing line after dyeing.

Method of use

The mercerized smoothing agent is used for finishing the fabric and can be carried out according to the conventional process. For example, the dosage is usually 10~20g/L, if the second dip or second dip. Dipping process: soak at room temperature for 15~30 minutes, dehydrate and dry, usually 1~2% (O.W.F.).

The specific process requests the user to adjust according to the sample.

Matters needing attention

1. Avoid using water with poor quality (e.g. the hardness of CaCO3 is higher than 100ppm), so as not to affect the finishing quality.

2. Wash the remaining alkali residue on the fabric as far as possible so as not to affect the finishing quality.

Storage, packing and transportation.

1. Storage: sealed and stored in a cool and ventilated place with a shelf life of not less than 6 months.

2. Packing: packed in plastic drum, net weight of 125kg/ pail.

3. Transportation: this product is transported by non-dangerous goods, and attention is paid to light loading and unloading.